Wastewater Engineers, Inc.

Products and MachinesRT-65-DB Manual Batch Treatment

- Requires only (15) minutes of non-skilled, attendant labor per batch

- Treats (65) gallons per Batch

- Dimensions: 36″ L x 36″ W x 72″ H

- 3/4″ NPT inlet and 1-1/2” NPT outlet fittings – allows for hard plumbing in/out

- Unit is equipped with a NEMA (12) enclosed Manual Motor Starter, receptacle plug for the sump

- pump, and an 115VAC Service power cord.

- Clean water discharge valve for discharge of processed water

- Separate sludge discharge valve for remaining sludge/processed water evacuation

- All fluids/sludge is discharged via gravity to a sludge cart, which resides below the mix tank. A

- perforated poly bag resides inside the sludge cart – thus, solids (sludge) is caught in the poly bag –

- while water is allowed to seep through the poly bag and into a collection sump.

- Sump pump is float-activated and will automatically transfer fluids from the RT unit to either recycle

- tank or to sewer. Sump pump is rated at 37gpm. (at 10′ of head)

- Electrical requirements are 115VAC service w/single plug-in cord (supplied w/unit)

- HO Package (Optional)

- Upgraded version of the above described is available as a total package including a control panel to

- replace the (above described) ‘On/Off’ switch with the following features:

- Reduced labor, requires only (5) minutes of attendance per batch

- Operator will push “fill start” button on the control panel that will utilize a fill pump and thus, transfer

- effluent from its source. The filling will continue until a ‘full’ level is attained – at which time the

- pump will stop and an indicator light will advise “RT Full”. Transfer pump is air operated. Pump will

- draw and pump effluents from 20 ft and deliver 15gpm@ 25 ft. of head. Pump is mounted to RT unit.

- Countdown, mixer/timer. May be set from 0 – 15 minutes. Switch turns on mixer and will shut off

- mixer upon completion of timer cycle.

- Canister bag filter (Model WE-625) for final polish of processed fluids. Unit is mounted to RT and

- will provide capability to capture ‘pin’ floc that may pass through poly bag sludge filter. Unit

- features a re-usable/cleanable bag.

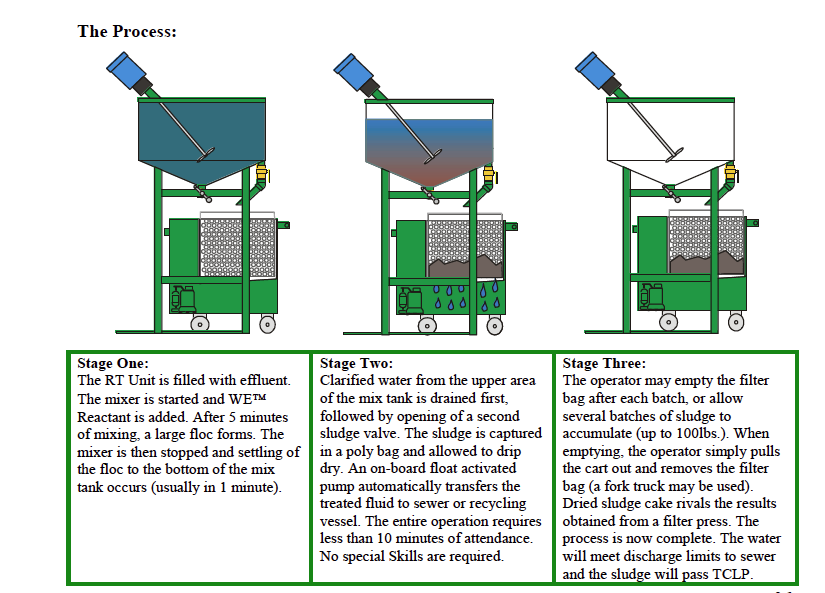

RT-65 DB Series

Manual Batch Wastewater Treatment Unit

- Simple, safe, and cost effective method to treat almost any aqueous based wastewater effluent

- Treats a drum of wastewater for less than $10.00

- No hazardous treatment by-products

- Guaranteed to meet discharge limits to local sewer

- Compact Design

- Low capital cost

- Low maintenance, available 3 year, 100% parts replacement warranty

- Ideal for metal working and grinding fluids, vibratory equipment and parts washing fluids, floor cleaning fluids, etc.

RT-65-DB

- HD steel construction

- Push botton mixer switch

- Pull out cart and bag filter

- Float activated discharge pump

- Requires

- 115VAC

- Measures 46″ I x40″ w x 84″ h

RT-65-HO

Upgraded version of the above described is available as a total package including a control panel to replace the (above described) ‘On/Off’ switch with the following features:

- Reduced labor, requires only (5) minutes of attendance per batch

- Operator will push “fill start” button on the control panel that will utilize a fill pump and thus, transfer effluent from its source. The filling will continue until a ‘full’ level is attained – at which time the pump will stop and an indicator light will advise “RT Full”. Transfer pump is air operated. Pump will draw and pump effluents from 20 ft and deliver 15gpm@ 25 ft. of head. Pump is mounted to RT unit.

- Countdown, mixer/timer. May be set from 0 – 15 minutes. Switch turns on mixer and will shut off mixer upon completion of timer cycle.

- Canister bag filter (Model WE-625) for final polish of processed fluids. Unit is mounted to RT and will provide capability to capture ‘pin’ floc that may pass through poly bag sludge filter. Unit features a re-usable/cleanable bag.

NOTE: Many waste streams require pretreatment – the removal of gross amounts of oils, solids and similar. WE, Inc. designs and supplies complete turn-key components, which will address these requirements. Please see your local sales engineer for details.

Highlights of the Series:

- Simple, safe and cost effective

- No hazardous by-products

- Guaranteed to meed discharge limits to local sewer

- Sludge is guaranteed to pass TCLP

- Compact Design

- Low maintenance, available 3 year, 100% parts replacement warranty

- Handles most aqueous based fluids

NOTE: Many waste streams require pretreatment – the removal of gross amounts of oils, solids and similar. WE, Inc. designs and supplies complete turn-key components, which will address these requirements. Please see your local sales engineer for details.