100% Satisfaction Guaranteed!

Wastewater Engineers, Inc. provides superior reliability and performance with our engineered systems and component equipment. As such we offer a standard (3) full year, 100% parts replacement for any component which fails to function as intended. Wastewater Engineers, Inc. reserves the right to request the return of malfunctioning parts. Important Notice: Remaining duration of (above) Guarantees and Warranties are null and void immediately if substitute supplies or treatments are used without express, written authorization from Wastewater Engineers, Inc.

Call us today! (248) 236-9800

Introduction to Wastewater Treatment

Industrial wastewater treatment is any process that separates and removes contaminants from industrial process waters, or effluent. These contaminants include oils, dissolved heavy metals, suspended solids and organic compounds. Either the local municipality or the Federal Government regulates the specific contaminants. A series of limits are set to determine the suitability for discharge. These limits must be met for the water to be legally discharged. If these limits are not met, the water must be pre-treated before being discharged, to remove the majority of the regulated contaminants. Although we are technically providing pre-treatment systems, we refer to them as treatment systems.

What makes Wastewater Engineers, Inc. different from other companies offering similar systems? We have a commitment to the industry. We specialize in this area, and can provide common sense advice derived from years of experience. We provide a written guarantee of our systems’ performance. We bring fluid management expertise to our clientele, providing added benefits and cost savings. We provide complete, turn-key systems, which handle the water from source to discharge. We provide excellent service after the sale, and back our systems with warranties up to 3 years.

We have adopted a three-phase approach to treating industrial wastewater. The three phases are Pre-treatment , Chemical Treatment, and Post-treatment.

Pre-Treatment

Free Oil And Soluble Oil

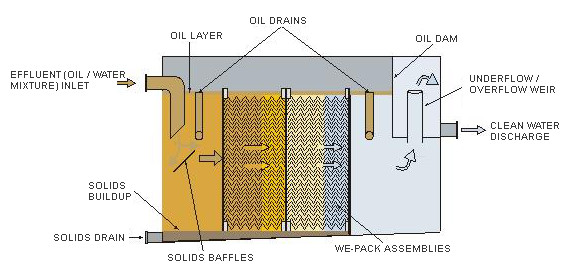

Often, it is necessary to remove gross oils from a waste stream prior to chemical treatment. We supply traditional belt and wheel skimmers and also an innovative honeycomb “on the flow” coalescer, which can separate up to 97% of free oils in the first pass. This range of “on the flow” coalescers are called L-OR and OR series. Emulsified oils and grease products require an emulsion breaker to achieve the floating characteristics of free oils. Once “popped” the oils may be easily skimmed or coalesced. Our WE-KAO-L product easily breaks that complicated emulsion, so that even the most difficult fluid can be treated.

Gross Contaminants And Debris

Often, it is necessary to remove gross solids from a waste stream prior to chemical treatment. Filtration and settlement are the two favored methods of reducing the solids content of wastewater. Our range of filters and settling tanks are made to suit each application.

Soluble Metals, Phosphates And Other Contaminants

In most instances we will recommend chemical precipitation to allow these contaminants to “fall” out. The range of our precipitants is very effective and less harsh than acidic/alkaline pH adjustments. Don’t forget; our RT clarification chemistry has an affinity for a wide range of soluble contaminants, so in many cases complicated precipitants may not be needed.

Chemical Treatment

Reactant Powder chemistry – Even excellent pre-treatment methodology cannot fully remove the necessary amount of contaminants to meet discharge limits to sewer, or recycling specifications. Suspended solids, typically 20 micron and smaller will not settle out of solution. Oil, even after any emulsions are split, is rarely below 100ppm. Dissolved heavy metals, even when precipitated do not fall readily from water, and do not filter readily. Our line of Reactant Powders capture and encapsulate those suspended solids, oils, and dissolved heavy metals into a large floc, which falls readily from water and filters with ease. The floc produced will pass TCLP criteria as non-leaching and non-hazardous. The treated water is sufficiently free of contamination to meet even the strictest of discharge regulations, and is often times an excellent candidate for reuse. Our RT equipment is designed to accommodate this phase of treatment easily and safely.

Post-Treatment

Post treatments can be either “polishing” of cleaned water, or pH adjustments. Some “ols”, that is; alcohols and glycols and such, have to pass through charcoal or other final capturing methods to finally strip out the impurities. Ammonia traces can be effectively removed with a zeolite column. Interestingly, we can adjust our chemical treatment to leave in soaps, detergents, inhibitors, and other expensive replenishment’s, giving you more savings. If bacterial contaminants are an issue, we supply either a chemical oxygenator or effectively remove the colony by passing the clean water through Ultra-Violet purifiers. An amazing number of options are open to us, individually or in combination.