Wastewater Engineers, Inc.

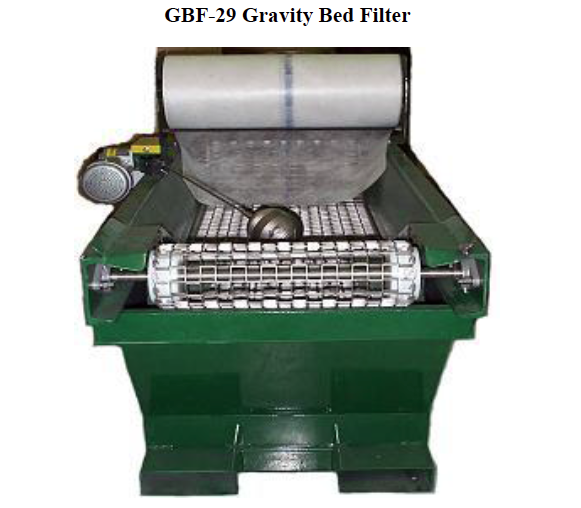

Products and MachinesThe GBF-29 Features

Basic Operation

Fluids Flow from a tank or sump on to the filter paper media, which captures the solids. Liquid flows through the filter media and into a base tank. The base is outfitted with a float-activated Sump pump. The Sump pump automatically returns clarified fluid to the original tank, sump, or downstream for further treatment or disposal. As solids accumulate on the filter media, a float connected to a proximity switch activates the conveyor bed index motor. This in turn pushes the paper and solids into a trash collection box or optional WE-Gondola. This simple and reliable technique requires minimal consumables and virtually no attendant labor.

Applications

- Production metal grinding and machining operations- collects grinding swarf and metal chips

- Floor cleaning effluent- separates sand, silt, paper, and similar solids

- Food processing- separates food processing debris from process fluids, e.g. meats, vegetables, fruits

- Equipment wash down- stamping die metal debris, construction equipment and auto wash, building cleaning, cement forming/grinding solids, reclaiming/recycling applications such as plastic recycling and scrap metals reclaiming.

Specifications

- 304 stainless steel filter bed conveyor provides rust-free service

- A deep bed design provides more flow capacity and reduced filter paper consumption

- Standard 3/10 hp, 35gpm @ 19’ of head, float activated sump pump. No need for operator to turn on or off as operations dictate.

- One cord plugs in to a standard wall socket (115VAC)

- Optional sump pumps, inlet and outlet plumbing available

- One year full parts replacement warranty

- Sloped clarified fluids Base tank means less stagnant fluids and odor

GBF Series Gravity Bed Filter

General Information

The GBF-29 Automatic Gravity Bed Filter from Wastewater Engineers, Inc. is designed for efficient, cost-effective solids separation. This equipment is simple to use and requires very little maintenance and consumable supplies. Gravity bed filtration has earned a reputation for time and labor savings versus canister filtration where bags require constant changing. Thus savings in labor and expensive replacement bags are realized when removal of gross amounts of solids is required in your operations. The automated function provides constant cleaning capabilities without need for attendant labor.