Wastewater Engineers, Inc.

Products and MachinesRT-65-DB Manual Batch Treatment

- Requires only (15) minutes of non-skilled, attendant labor per batch

- Treats (65) gallons per Batch

- Dimensions: 36″ L x 36″ W x 72″ H

- 3/4″ NPT inlet and 1-1/2” NPT outlet fittings – allows for hard plumbing in/out

- Unit is equipped with a NEMA (12) enclosed Manual Motor Starter, receptacle plug for the sump

- pump, and an 115VAC Service power cord.

- Clean water discharge valve for discharge of processed water

- Separate sludge discharge valve for remaining sludge/processed water evacuation

- All fluids/sludge is discharged via gravity to a sludge cart, which resides below the mix tank. A

- perforated poly bag resides inside the sludge cart – thus, solids (sludge) is caught in the poly bag –

- while water is allowed to seep through the poly bag and into a collection sump.

- Sump pump is float-activated and will automatically transfer fluids from the RT unit to either recycle

- tank or to sewer. Sump pump is rated at 37gpm. (at 10′ of head)

- Electrical requirements are 115VAC service w/single plug-in cord (supplied w/unit)

- HO Package (Optional)

- Upgraded version of the above described is available as a total package including a control panel to

- replace the (above described) ‘On/Off’ switch with the following features:

- Reduced labor, requires only (5) minutes of attendance per batch

- Operator will push “fill start” button on the control panel that will utilize a fill pump and thus, transfer

- effluent from its source. The filling will continue until a ‘full’ level is attained – at which time the

- pump will stop and an indicator light will advise “RT Full”. Transfer pump is air operated. Pump will

- draw and pump effluents from 20 ft and deliver 15gpm@ 25 ft. of head. Pump is mounted to RT unit.

- Countdown, mixer/timer. May be set from 0 – 15 minutes. Switch turns on mixer and will shut off

- mixer upon completion of timer cycle.

- Canister bag filter (Model WE-625) for final polish of processed fluids. Unit is mounted to RT and

- will provide capability to capture ‘pin’ floc that may pass through poly bag sludge filter. Unit

- features a re-usable/cleanable bag.

RT 100 – 1000 Series

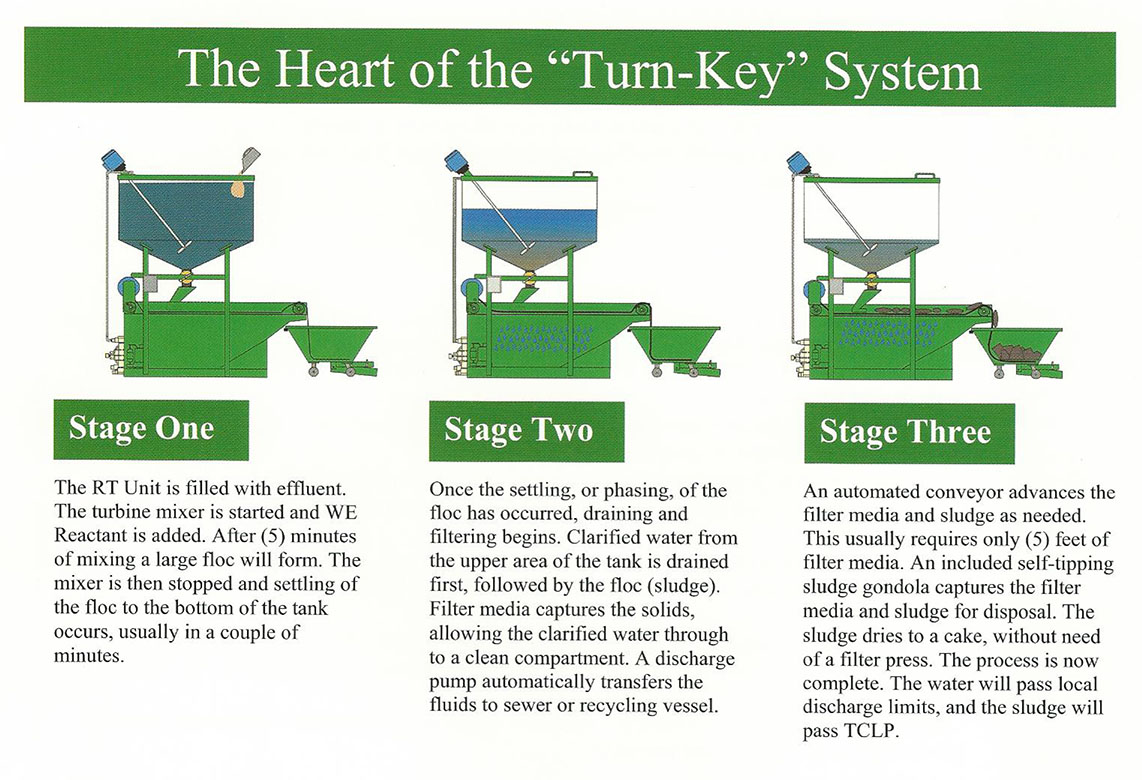

These units are semi-automatic batch treatment machines, capable of running 2 batches per hour. The RT-100 HO is a 100 gallon unit, the RT-350-HO is a 350 gallon unit and so forth.

All units feature:

- HD Steel Construction

- Designed to be operated by custodial personnel

- Allen Bradley Controls

- Push button auto fill function

- Auto indexing filter bed

- Rinse down package

- Float activated discharge pump

- Final stage canister fill

This series consist of the following units:

- RT-100-HO

- RT-200-HO Show above

- RT-350-HO

- RT-500-HO

- RT-750-HO

- RT-100-HO

Highlights of the series:

- Simple, safe, and cost effective

- Fully Automatic packages available

- Many labor saving features and options

- Requires only 10 minutes of attendant labor per batch

- No hazardous by-products

- Guaranteed to meet discharge limits to local sewer

- Sludge is guaranteed to pass TCLP

- Low maintenance, available 3 year, 100% parts replacement warranty

- Handles most aqueous based fluid

NOTE: Many waste streams require pretreatment – the removal of gross amounts of oils, solids and similar. WE, Inc. designs and supplies complete turn-key components, which will address these requirements. Please see your local sales engineer for details.