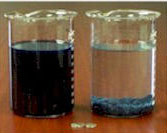

Reactant Powders The heart of the Wastewater Engineers, Inc. system is our clay based Reactant Powder. When mixed with wastewater, these powders form a heavy floc, which removes the contaminants and encapsulates them into an easily filtered solid. Shown here is one of our Reactant Powders and an ink wash water that has been chemically treated. Not only does the water appear clean, it is now sufficiently free of oils, dissolved heavy metals, and solids, to go to sewer.

The following is a brief overview of the chemistries involved and how they work. Our Reactant Powder is a clay based chemical that removes suspended solids, emulsified oils, and dissolved heavy metals from water. When mixed in water, the powder chemically reacts with the contaminants and forms a large floc. This process is known as flocculation and encapsulation. The result is a sludge cake which is suitable for disposal in non-hazardous landfills, and treated water which is sufficiently free of oils, suspended solids, and heavy metals to be discharged to a municipal sewer.

The treated water is also an excellent candidate for recycling, since soaps and other expensive chemicals are left untouched during the treatment process. This allows for reuse of the water in the production process without need to add more chemicals. After factoring in carry-off and spillage, a realistic savings of 85% on chemical replenishment is typically realized.

Flocculation and encapsulation is a process of waste fixation. The Wastewater Engineers, Inc. Reactant Powder coats coagulated droplets of oil and other contaminants with a webbing that permanently traps the waste. The webbing forms by chemical reaction just after flocculation. The floc starts a curing process which improves with age.

The encapsulation process produces a safe, non-leaching sludge that can be disposed of in non-hazardous landfills. This type of disposal costs 3 to 5 times less than the disposal costs of concentrates or leaching sludge in hazardous waste landfills and eliminates the possibility of groundwater contamination. Future liability for environmental cleanup is also eliminated. The sludge produced by the Wastewater Engineers, Inc. treatment process is guaranteed to meet TCLP compliance for disposal to landfills.

Equipment

- LOR Series Coalescers

- Model S-222 A & E Series Lift Stations

- Model #461 Dumping Station

- The GBF Series Gravity Bed Filter

- Canister Filters 625 & P830

- Canister Filters 1036 & 1240

- The WE-MC-S Solids Filter & Dewatering Cart

- ST-Tanks: Settling And Filtration System

Reactant Powder

Before and After Reaction